The Importance of Water Treatment

Whether you utilize steam boilers, make use of cooling towers, need deionized water or something else, water treatment is an important part of making sure your business runs smoothly and efficiently. Failing to treat water correctly can lead to many problems that might cause unwanted plant downtime, premature equipment failure, or a loss of efficiency. Issues related to poorly treated water might be an inconvenience, but is water treatment really necessary? The answer is almost always “yes”! Water that is left untreated, or that is not treated correctly, is susceptible to a number of common water treatment issues that range from trivial to catastrophic. To avoid the latter, and to save yourself some headaches and financial setbacks in the future, water treatment is a must.

What’s in Your Water?

Water treatment issues are varied and many, but a few tend to pop up more commonly than others. All water is different, and many factors determine how your water looks, feels, smells and acts within your water applications. That being said, all water is susceptible to issues if left untreated. Find out what issues we see most commonly, and click the links to find out more about these issues and how you can troubleshoot them.

Scale

Water can contain a variety of dissolved substances, including minerals like calcium and magnesium, which can deposit on the surfaces of pipes and water applications to form scale, a buildup of solid scale-like material on the surface of water applications like a heat exchanger. These deposits can build up and reduce efficiency, and even damage equipment.

Corrosion

Corrosion occurs as water slowly dissolves metals within a water system, leading to deterioration, weakening, or even rupturing. The exact damage caused by corrosion depends on several factors, including specific water chemistry, water temperature, flow rate, and more. If corrosion gets out of hand, it can lead to leaks or burst pipes.

Fouling

‘Fouling’ is a general term used to describe the presence or accumulation of unwanted material in water or on a component such as a heat exchanger. This can include scale, general dirt and debris, dissolved metals, or biological matter or bacteria, and can impede the usefulness of an application.

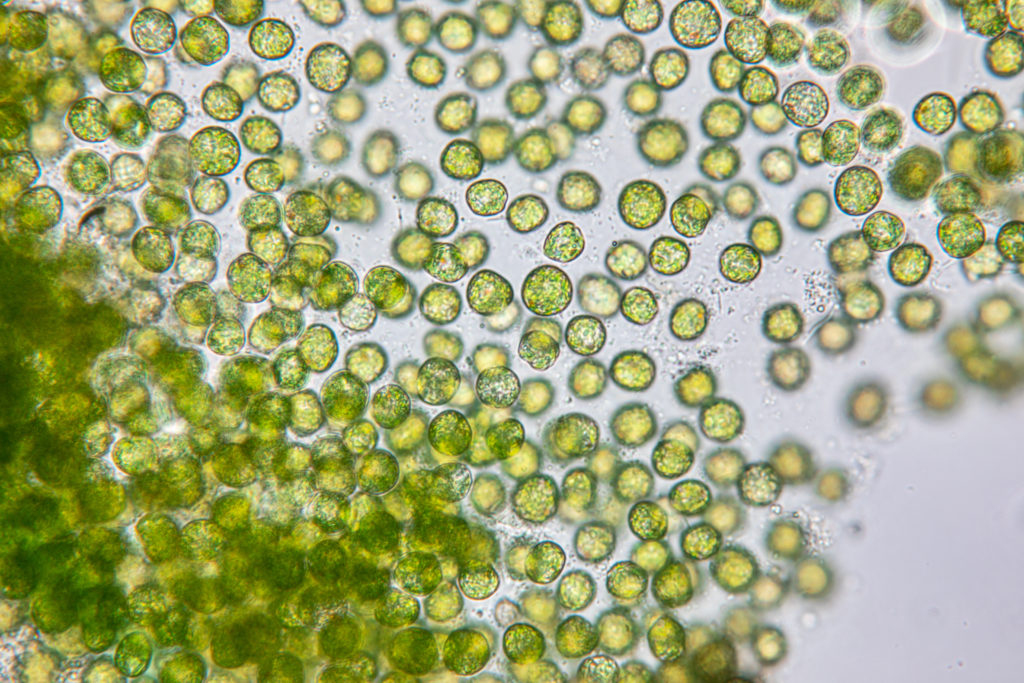

Biological Growth

Biological growth is the undesirable growth and development of microorganism, plants, algae, biofilm, or other biological components in a water system. This bio-growth can negatively impact efficiency, as well as lead to the formation of harmful bacteria such as legionella.

Is your Water Safe?

Protecting your water-based applications from these common water treatment issues will help ensure their maximum working lifespan, as well as save trouble for you and your team. A water treatment specialist can analyze your water and examine your applications to create a custom treatment plan to suit your specific needs. If you have any questions or want to know more about water treatment, contact us. One of our water treatment specialists would love to hear from you!

Why Tanks and Sumps Become Biofilm Nurseries

Tanks and sumps are some of the most biologically active areas in industrial water systems. Despite chemical treatment, these zones frequently become biofilm nurseries—protected environments where bacteria thrive, spread, and seed the rest of the system. Low Flow = High Risk Biofilm loves low-velocity conditions. Tanks and sumps often experience…

Why Biofilm Grows Even With Biocide

Many industrial facilities assume that regular biocide feed prevents biological growth. Yet biofilm still develops—even in chemically treated systems. The reason lies in how biofilm behaves, not in a lack of chemicals. Biofilm Shields Microorganisms Once bacteria attach to a surface, they produce a protective matrix that limits biocide penetration.…

What Causes DI Bottles to Exhaust Too Fast

Deionization (DI) bottles are designed to deliver high-purity water reliably, so when they exhaust faster than expected, it’s a sign of upstream problems. Rapid exhaustion increases operating costs, disrupts production, and often masks deeper system issues. High Ionic Loading from Feedwater The most common cause of fast DI exhaustion is…

The Difference Between Pretreatment and Treatment

Pretreatment and treatment are often lumped together, but they serve very different roles in industrial water systems. Confusing the two leads to poor performance, higher costs, and premature equipment failure. What Pretreatment Really Does Pretreatment protects downstream equipment. Its job is to remove or reduce contaminants—such as hardness, iron, chlorine,…

Why Your RO Sanitation Won’t Hold Residual

If your RO system won’t maintain a sanitizer residual, the issue is rarely the chemical itself. Loss of residual points to system demand exceeding sanitizer capacity, usually due to biological load or material compatibility issues. Biofilm Demand Is Often Underestimated Biofilm consumes sanitizers rapidly. Even if surfaces look clean, mature…

How to Diagnose Membrane Scaling vs. Fouling

Reverse osmosis (RO) membranes lose performance for two main reasons: scaling or fouling. While the symptoms may look similar, the corrective actions are very different. Correct diagnosis is critical to restoring system performance without causing damage. Understanding the Difference Scaling is caused by inorganic mineral precipitation—commonly calcium carbonate, calcium sulfate,…

How to Lower Cooling Tower Chemical Costs Without Risk

Cutting cooling tower chemical costs is a common goal—but doing it the wrong way leads to scale, corrosion, fouling, and unplanned downtime. The key is optimization, not underfeeding. Increase Cycles of Concentration Safely Many towers operate conservatively due to fear of scaling or corrosion. With proper water analysis and program…

How Industrial Facilities Can Cut Water Use by 30 Percent

Water reduction targets are becoming a reality across industrial sectors. The good news? Many facilities can cut water use by 30% or more without disrupting production—if they focus on the right areas. Maximize Reuse Before Replacement Final rinse water, RO reject, cooling tower blowdown, and once-through cooling water are often…

Preventing Irrigation Emitter Fouling with RO/UF

Industrial and large-scale irrigation systems increasingly rely on reclaimed or impaired water sources. While reverse osmosis (RO) and ultrafiltration (UF) make reuse possible, emitter fouling remains a major challenge without proper design and operation. Why Emitters Plug Emitter fouling is caused by a combination of suspended solids, biological growth, and…

Why Your Boiler System Has Elevated Iron in Condensate

Elevated iron in boiler condensate is a red flag that something upstream is failing. While iron is expected in raw makeup water, condensate should be essentially iron-free. When iron shows up there, it usually points to corrosion, oxygen intrusion, or operational gaps that can quickly damage boilers, steam traps, and…